SBR PROCESSING SYSTEM

Wastewater treatment technology is becoming more and more, especially towards and applying the Jokaso standard of Japan, instead of using toxic chemicals. Wastewater treatment using SBR technology is being applied currently. One of the advanced technologies commonly used in wastewater treatment systems in hospitals, industrial zones and even domestic wastewater in developed countries is SBR wastewater treatment technology.

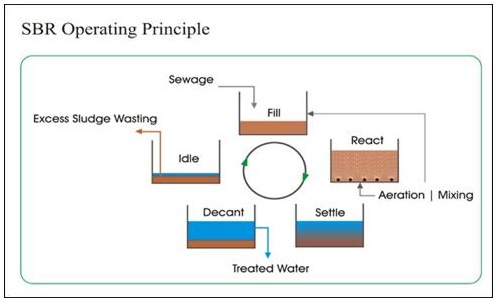

The SBR wastewater treatment technology includes two tank clusters: Selector tank cluster and C - tech tank cluster, SBR tank (Sequencing Batch Reactor) is a biological wastewater treatment tank under the reaction process of continuous batch. This is a form of Aerotank tank. Water is firstly taken into the Selector tank and then through the C - tech tank. Selector tank will be continuously aerated to facilitate the process of aerobic treatment takes place. The water is then transferred to a C-tech tank. The SBR tank works in a cyclical cycle with five phases: Filling, aeration, settling, water withdrawal, and rest. Each rotational step will be carefully selected based on professional knowledge of biological response. SBR system requires periodic operation to control the processing. Cycle activity controls the entire stages of the processing cycle. Each rotational step will be carefully selected based on the professional knowledge of biological response.

Advantages of treatment process of SBR technology

- Simple and sustainable structure

- Easy operation and reduced human effort.

- Strongly design.

- Partly installation is allowed and easy for expansion

- Highly effective treatment of pollutants.

- Competitive installing and operating price.

- High ability to remove nitrogen and phosphorus.

- Stable and flexible by load changing.

.jpg)

Figure: SBR tank in aeration process

Advantages in treatment process of SBR wastewater treatment technology

Flexibility in treatment process. The anaerobic conditions in stage of wastewater inputting and mixing will help to perform the nitrate elimination and phosphorus decomposition. During the aeration phase, nitrification and phosphorus absorption into biomass will take place. The phosphorus treatment process in SBR tank depends much on the input amount of organic matter and the amount of nitrate present in the sludge retained from the previous work cycle. Process of nitrification, nitrate elimination and phosphorus settlement are all closely related to low organic loading amount for SBR system. If the input amount of organic matters is relatively stable, the organic loading amount will depend largely on sludge content in the reaction tank.

Thanks to the Jokaso technology transfer, the wastewater can be purified through processing thanks to anaerobic and aerobic microorganism to remove organic, inorganic matters and harmful bacteria in water to help protect the environment. At the same time, it helps enterprises to select more solutions in wastewater treatment design based on Japan's standards to ensure output water quality.

SBR technology is suitable for large-scale centralized wastewater treatment stations with large capacity such as wastewater treatment for industrial zones, residential areas, urban areas, etc.